5 steps to achieve a digital and optimized supply chain

Is your supply chain challenged and running the same routes without getting any more streamlined and smoother? Are you looking for new ways to improve its condition in the long term?

We hear you.

The world keeps changing into a digital entity and with that, the chemical industry also needs to adapt to new methods. Many issues, like lack of visibility, process complexity, and demand and supply unpredictability affect the supply chain. Also, the pressure of managing a huge database is a real challenge. Not to mention the recession, which the top economic experts [1] predicted for 2023 with recovery to be unlikely in 2024.

On top of this, also regulatory developments have an impact. An example of that is the German Supply Chain Act Due Diligence and what it means for the chemical manufacturing industry. While an EU directive is being negotiated in the European Parliament, the German Act already affects also non-German companies.

With all these factors affecting your business, keeping the overview and control is key.

That’s why we have listed 5 useful steps to help you achieve supply chain optimization including due diligence regulatory compliance.

Ready? Let’s go!

Signposts for your reading comfort:

Step 0: Be aware of your status quo and believe that recession-proofing is possible, even though it may be difficult for an industry that is worldwide in scope, highly specialized, and full of market competition.

Step 1: Assess the characteristics of the organization together with the capability, capacity, and cost areas of the current organization and establish metrics that will not only create visibility into the supply chain but also drive those structural changes that make cost savings sustainable in the long term.

Step 2: Apply a globally unified strategic sourcing strategy which, combined with the freedom to choose your suppliers, results in a streamlined pool of suppliers to achieve better control over supplier choice and relationships.

Step 3: Improve logistics by looking at transportation network analytics and at the strategy for negotiating with carriers: based on this analysis you can determine where to place warehouses to minimize transportation issues and optimize your logistics process.

Step 4: Gain insight into the full plan-buy-make-move-fulfill supply chain through advanced data analysis, modeling, and predictive techniques and you can develop recession resistance through sustainable procurement, logistics, and technology initiatives.

Step 5: Apply the AirPlus Virtual Cards Procurement payment solution as the digital driver by nature to help achieve the common goal of purchasing, finance, and treasury teams: save time while maintaining transparency throughout the process and managing the available budget.

Navigating through recession

The starting point — or step zero — is to be aware of your current condition.

It has been and will continue to be a tough exercise for the chemical industry to stay in shape and live up to expectations. The continuous challenge it faces is that it’s linked to almost every other industrial segment. Therefore, it not only affects but is also impacted by slowing demand, inflation, and supply chain instability across the global economy.

The current situation shows that most chemical companies are reporting strong revenue growth, fueled by significant pricing increases; however, they also indicate rising raw materials, energy, and logistics costs as current concerns, combined with declining demand in most segments.

Furthermore, in a period of recession and inflation, the following major challenges are examples of what can hinder the chemical industry from moving ahead: [2]

- Suppliers are feeling free to accept the companies they want to work for, and companies are feeling threatened.

- Logistics issues are interfering with both procurement and delivery — in other words, both ends of the plan-buy-make-move-fulfill supply chain are at risk.

- Companies are slowly automating but lack the data they need to make significant changes; so they are automating less-than-optimal systems.

Recession-proofing may be difficult for an industry that is worldwide in scope, highly specialized, and full of market competition but it is possible. After more than a decade of economic growth, most companies lack a plan for dealing with a recession. In many cases, major players on the executive team have never dealt with a recession in the first place.

And still, sustainable recession- and inflation-proofing is achievable. End-to-end supply chain optimization that improves the liberty of choosing suppliers with relationships, logistics, network analytics, and digitalization that includes your payment processes, gives your organization the flexibility it needs to survive recession and inflation.

In addition, your organization can integrate several activities in your optimization journey to comply with supply chain due diligence laws and ensure responsible and sustainable operations.

Step 1: Measuring what moves your business

Once the mind is set on it, the first step in optimizing a supply chain is to find out what works and what doesn’t, and that requires insights.

Many chemical companies lack the company-wide key performance indicators (KPIs) and metrics that will provide the insights they need; for others, the necessary data is available but closely held in silos; and for others, the data is accessible, but the company lacks an operating model to effectively apply it.

The following two assessments not only create visibility into the supply chain but also drive those structural changes that make cost savings sustainable in the long term.

- Analyzing the organization, roles and responsibilities, systems and tools, business processes, performance management, and capabilities and culture enables a company to establish KPIs and metrics, build collaboration, improve decision-making, and identify initiatives that will save costs.

- Analyzing the capability, capacity, and cost (3C) of current operations helps to pinpoint those areas that are core to company operations, those that should be outsourced, and those that should be kept in-house regardless because they provide a competitive or fiscal advantage. [3]

And while you are in that exercise of mapping out your supply chain, it’s crucial to also integrate the due diligence analysis on your supply chains to identify potential human rights or environmental risks. With that visibility added to the results of the assessments mentioned above, you will already have a good overview and foundation for the rest of the optimization journey.

Step 2: Improving your procurement process for better control of supplier choice and relationships

During a recession, chemical companies feel pressure all along the plan-buy-make-move-fulfill supply chain. Suppliers, on the other side, often cut back capacity and are selective about whom they supply. But chemical companies like yours still have the right to initiate win-win negotiations with suppliers and customers alike.

The formula to improve supply chain cost control?

A unified strategic sourcing strategy combined with the freedom to choose your suppliers provides you with a streamlined pool of suppliers.

What’s more, expanding the sourcing strategy to one with a global focus unifies procurement practices throughout the company and allows the procurement specialists to approach suppliers in line with the company’s overall goals and ensure that savings gained with one supplier relationship are not consumed by losses from another relationship.

Research indicates that all these procurement improvements together can reduce direct material costs by 4% to 10% and indirect categories, including packaging and logistics, by 8% to 12%. [2]

While implementing those strategies with the selected pool of suppliers and based on the supply chain assessment results, it’s imperative to integrate policies and procedures addressing the identified risks on due diligence. This may include developing a supplier code of conduct, setting expectations for suppliers to adhere to labor and environmental regulations, and putting in place processes to monitor compliance.

In that practice, it’s key to keep engaging with suppliers and building strong relationships to ensure that they understand and are committed to the company's policies and procedures. This may involve providing training or support to help suppliers improve their practices, sharing best practices, and fostering transparency and trust in the supply chain.

Step 3: Improving logistics to actively address supply chain disruptions

Logistics impact every link in the plan-buy-make-move-fulfill supply chain, from the process of coordinating the receipt of raw materials at the very beginning to the delivery of finished products at the end.

By looking at transportation network analytics and at the strategy for negotiating with carriers, you can determine where to place warehouses to minimize transportation issues and optimize your logistics process. Because many chemical products are highly dangerous, transportation logistics are complicated by various import, export, and safety regulations that limit travel domestically and across the globe.

Good communication and a solid forecasting process are crucial to the successful coordination of supply and delivery in the chemical industry. Freight terms, minimum quantities, and customer forecasts can require a more disciplined approach than sales want to impose but may significantly increase reliability and delivery performance. For operations, transparency, and visibility of the supply chain across functions depends on good data management and enforcement of policies.

Step 4: Digitalizing and analyzing data to bring visibility to the supply chain

The Gulf Petrochemicals and Chemicals Association (GPCA) reports that 64% of chemical companies have undertaken digitalization initiatives but less than 44% of all chemical companies have moved beyond the pilot stage, an indication of digital immaturity. Yet, “digitalization is a critical asset,” according to GPCA. [4]

Problems must be known before they can be solved. A digitally enabled supply chain has the potential to bring products to market faster, reduce waste, increase productivity, and improve forecasting and decision-making if it is approached correctly.

Before getting there, what’s seen as the biggest problem in creating a digitally enabled supply chain is not the choice of the technology — although that can be confusing. Instead, problems arise from data being trapped in separate systems instead of flowing across the enterprise.

Employees need to think and share beyond their own functions. Another issue is making sure the data collected is meaningful; otherwise, a company may be installing systems that do not work and the leadership team will still lack the information and control they need.

Through advanced data analysis, modeling, and predictive techniques, chemical companies gain insight into the full plan-buy-make-move-fulfill supply chain and develop recession resistance through sustainable procurement, logistics, and technology initiatives.

Furthermore, in the data analysis parameters, the monitoring and reporting about the supplier’s due diligence compliance must be considered too. This may involve updating policies and procedures based on new information or feedback, conducting regular risk assessments, and engaging with stakeholders to ensure that their practices align with emerging best practices and evolving expectations.

Step 5: Paying with virtual credit cards to maintain visibility for all procure-to-pay stakeholders

With your company’s digitalization efforts, payment is an indispensable element in that process too. Payment processes are becoming more digital as businesses strive for efficiency and success, so keeping track of which orders have been paid to which supplier is important for your company too to successfully monitor and manage these processes.

The key to successfully digitalizing your payment process is considering and understanding the role of each stakeholder in the payment process — end-to-end.

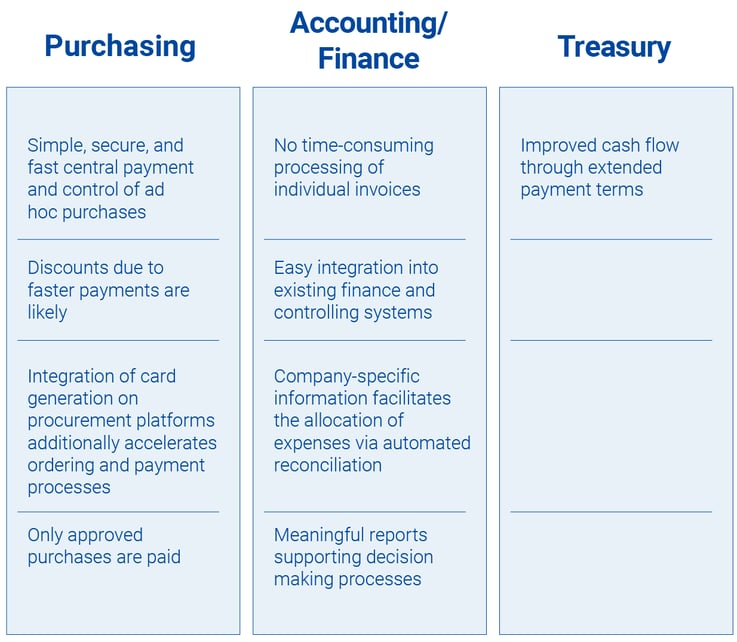

This means that there are opportunities for all stakeholders working in the procure-to-pay process to benefit: from the request and processing of the purchase order by the purchasing department, to the cost allocation by the finance team as well as the cash flow and working capital management by the treasury department.

Their common goal? Saving time while maintaining transparency throughout the process and managing the available budget.

The AirPlus Virtual Cards Procurement payment solution is the digital driver by nature to help achieve this goal.

The below overview illustrates how the stakeholders along the supply chain process in your company can easily benefit in their role from virtual cards and their enhanced transaction data without any impactful system and process changes.

Improving supplier relations with AirPlus Virtual Cards Procurement

Using AirPlus Virtual Cards Procurement to make payments is beneficial for suppliers too.

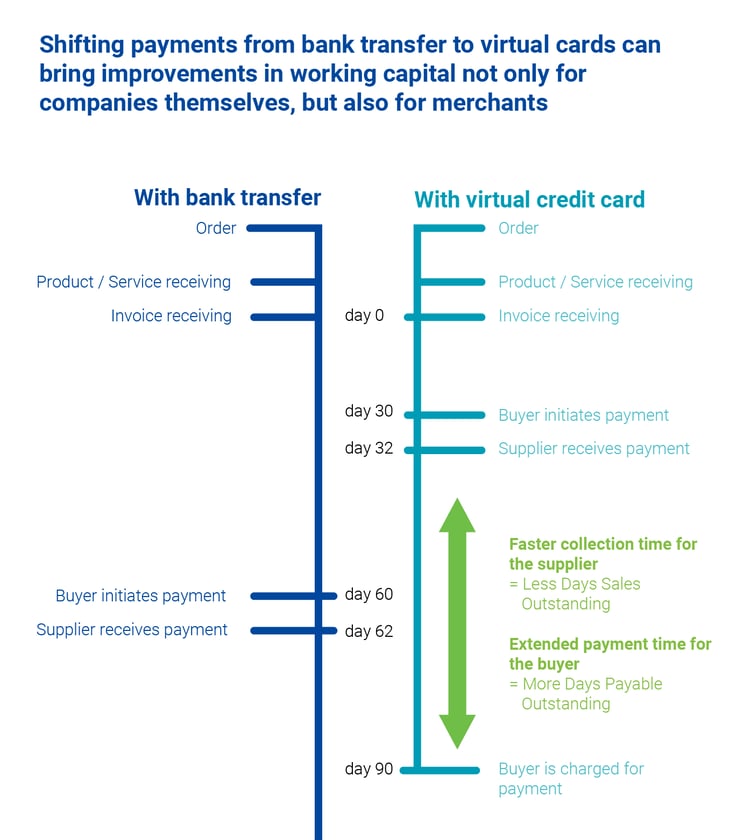

With virtual credit cards, your company can increase the days payables outstanding (DPO) and reduce the days sales outstanding (DSO) for your suppliers simultaneously.

Further advantages of virtual cards for suppliers are:

- Better data facilitates and accelerates the process of associating incoming payments and invoices.

- More control and visibility

- Save time and money: Fewer resources are needed to track payment status. The dunning process is completely eliminated thanks to the immediate payment via virtual cards.

- Acceptance of card payments can help suppliers acquire new customers since paying by card is an attractive option for many companies.

Reaching the finish line with a winning supply chain

Congratulations! You have now made it to the finish line with a supply chain that is fit enough to keep up with today’s pace in challenging circumstances.

Now that you know your organization inside and out as well as your strong network of suppliers thanks to implemented due diligence measures and optimized assessment metrics, you can stay on top of your game and ahead of whatever the future will bring.

On top, payment via AirPlus Virtual Cards Procurement shows its value throughout the entire procure-to-pay cycle and to your suppliers too, thanks to continuous and enhanced visibility of your procurement costs, benefitting the cash flow on both sides of the equation.

Want to learn more about how virtual payment pays off for your supply chain to stay fit going forward?

Get in touch now or get more information in our Supply Chain Due Diligence Hub by clicking the button below.

Sources:

[1] What’s the Chance of a Recession? Here’s What Economists Are Saying | The New York Times

[2] Three Keys to Recession Proofing the Chemical Industry Supply Chain | SGS Maine Pointe

[3] How Chemical Companies can Prepare for the Challenges of Recession | SGS Maine Pointe

[4] The latest developments in the GCC chemical industry’s 4.0 transformation | GPCA

.jpg?width=375&height=180&name=iStock-1497172728%20(3).jpg)