The Supply Chain Due Diligence Act: How virtual payment can soften its impact

Untangling the knots in your chemical manufacturing supply chain keeps you busy around the clock these days. Shortages, shipping delays, and higher prices everywhere make it challenging to keep the overview and end-to-end process visibility. Not to mention meeting the obligation to comply with regulatory standards.

An example of a patchwork of standards that recently added itself to this collection is the Supply Chain Due Diligence Act (or ‘Supply Chain Act’; Lieferkettensorgfaltspflichtengesetz / LkSG) which has already come into force in Germany. e info on the Directive on

The Act has been the topic of conversation for a while now, referring to all-around standards to be adhered to by companies, from human to labor rights as well as sustainability standards.

With this article, we will bring some clarity to you: to whom and when does the Act apply and why has it been introduced? What does it mean for companies like yours in the chemical manufacturing industry in particular? e e (CSDD) for a more international p

Even though the Act has come into force in Germany for now, if your company is in another country, you still may want to read on as the EU is next: With the German Act as a template [1], The European Commission has proposed the Europe-wide directive governing duties of care in the supply chain which is currently in negotiation at the European Parliament. The directive applies to large EU companies and non-EU companies active in the EU and has the purpose to be transposed into national law after reaching an agreement.

Let’s now explore what is in the Act’s pipeline.

Signposts for your reading comfort:

The German Supply Chain Act Due Diligence has come into force on January 1st, 2023, obliging companies to assume greater responsibility for compliance with human rights standards, such as the prohibition of forced and child labor, along with their entire value chains in the future.

The Supply Chain Act requires the implementation of comprehensive measures for risk analysis, prevention, and remediation of any violations in the company’s business area and in relation to direct and indirect suppliers along its value chain.

Chemical companies face supply chain challenges due to the several intermediaries that are involved as well as multiple layers of suppliers and sub-suppliers, which can make it difficult for chemical manufacturers to trace their supply chains and identify potential risks related to human rights or environmental impacts.

The Act has received mixed responses from the chemical industry. A CHEMonitor survey has indicated that the majority of the top managers surveyed support the Act’s purpose. However, concerns exist about liability, lack of supplier alternatives and specifically medium-sized chemical companies fear the high level of bureaucracy. For those medium-sized companies that are indirectly affected, the law represents a major challenge that can only be mastered with higher-level IT solutions.

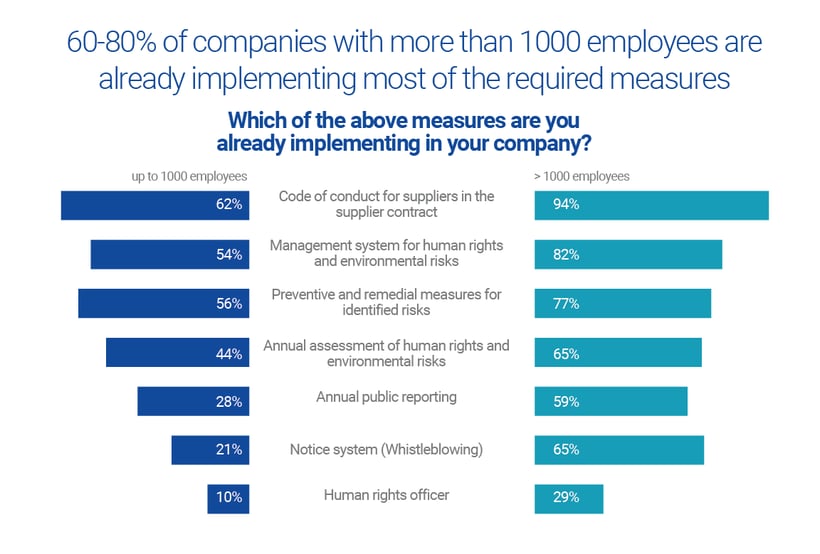

Today, 60-80% of the chemical companies with more than 1000 employees have already integrated most of the required measures in their business.

Virtual payments provide end-to-end visibility over spending. AirPlus Virtual Cards Procurement helps you achieve the transparency you need with billing reports for easy cost allocation, untangling the knots in your supply chain with various orders and suppliers you deal with on a daily basis. On top of this, AirPlus’ solutions can also help your organization report on your sustainability and compliance efforts, which is important for meeting the Act’s regulatory requirements and demonstrating a commitment to responsible business practices.

For whom and since when is the Supply Chain Act in force

Since January 1st, 2023, the Act applies to all companies with a head office, principal place of business, administrative headquarters, registered office, or branch office in Germany that employ at least 3000 employees in Germany across the group.

Starting January 1st, 2024, it will also affect all German companies with more than 1000 employees.

The German Act also applies to foreign companies if such companies have a branch office operating in Germany and, as a rule, employ in Germany more than 3000 (starting in 2024 more than 1000) persons. [2]

The law applies both to the company's own business, to direct and in some cases also to indirect suppliers.

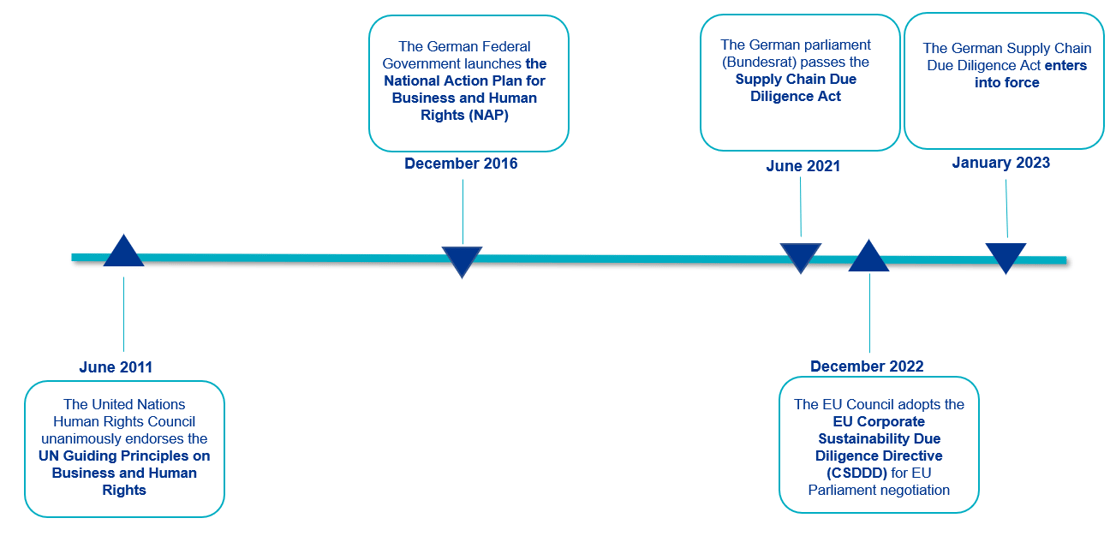

National Action Plan powering the Act

Before we go to the roots of the Act, what does the law term "due diligence" mean? In the dictionary, we find: "the care that a reasonable person exercises to avoid harm to other persons or their property". [3]

With this due diligence on top of mind, the ‘National Action Plan on Business and Human Rights’ (NAP or Nationaler Aktionsplan Wirtschaft und Menschenrechte) actually represented the foundation for the Supply Chain Act by the German Federal Government back in 2016, to contribute to more socially correct globalization together with companies.[4]

The NAP is based on the United Nations Guiding Principles on Business and Human Rights. Corporate responsibility lies at the center of the plan next to the state’s protection obligation and judicial as well as extrajudicial remedies. The German government supports enterprises in fulfilling this responsibility. In cooperation with industry sectors that face particular human rights risks, specific guidelines are currently being developed for use in practice.

However, a survey of businesses conducted by the Federal Government over several years (NAP monitoring), revealed that less than 20% of German companies with more than 500 employees comply with their voluntary commitment to corporate due diligence.

Because of this result, the German parliament passed the ‘Supply Chain Due Diligence Act’ at the end of June 2021 for improving the protection of human rights along global supply chains.

Accordingly, German companies are obliged to assume greater responsibility for compliance with human rights standards, such as the prohibition of forced and child labor, along with their entire value chains in the future.

The EU Commission proposed a directive on Europe-wide corporate sustainability due diligence in February 2022, which the EU Council adopted as a general approach in December last year and was the starting sign for negotiations with the European Parliament.[5]

Measures for monitoring compliance

The Supply Chain Act requires the implementation of comprehensive measures for risk analysis, prevention, and remediation of any violations in the company’s business area and in relation to direct and indirect suppliers along its value chain. To comply with the Supply Chain Act, chemical companies need to be active in nine areas: [6]

- Set up a risk management system for their own company and direct suppliers,

- Establish passive risk monitoring for indirect suppliers,

- Adopt a human rights strategy for the company,

- Anchor preventative measures for the company itself within processes and define supplier-specific measures,

- Develop a concept for remedial measures in the event of violations (for the company itself, direct suppliers, and indirect suppliers),

- Ongoing documentation with respect to compliance with duties of care,

- Annual report about the fulfillment of duties of care,

- Establish a complaints process,

- Define responsibility for risk management.

Companies violating the Supply Chain Act face the threat of fines. They can amount to up to 2% of the global annual turnover. In addition, companies may be excluded from the awarding of public contracts.

The German Federal Office of Economics and Export Control is responsible for checking whether the Supply Chain Act is being complied with. It investigates breaches, inspects reports, and checks whether omissions are being resolved.

Chemical supply chain challenges

Due diligence is indeed becoming increasingly important in the chemical industry next to clear end-to-end process visibility and procurement process transparency, as companies seek to ensure that their products are produced and distributed in a responsible and sustainable manner in a growing digitalized world.

The road to arrive at ticking off all the boxes for this purpose is not without obstacles. The following challenges in the chemical manufacturing supply chain may sound familiar.

Throughout the supply chain, from planning to production to logistics and distribution and in the end to the sales, several intermediaries may be involved such as logistics providers, customs brokers, and other third-party service providers.

In addition, there may be multiple layers of suppliers and sub-suppliers, which can make it challenging for chemical manufacturers to trace their supply chains and identify potential risks related to human rights or environmental impacts.

Business barometer measuring perceived Act pressure

Considering the complexities and the challenges of the chemical industry’s supply chain, it’s not very surprising that the Supply Chain Act has been received with a mixed response in the German chemical industry.

Indeed, the Act has significant effects on the chemical industry in Germany and this becomes evident from the results of the performed survey for the 37th CHEMonitor Trend Barometer among top managers of the German chemical industry in September and October 2021 with the new Act as main study topic, newly passed in June of that year.

In this CHEMonitor survey [7], representatives from the chemical sector were also asked about the biggest expected challenges in connection with the implementation of the Supply Chain Act.

Of the chemical companies surveyed, 83% said they saw the high level of bureaucracy as a potential challenge. The expected bureaucratic effort poses personnel and financial problems, especially for medium-sized chemical companies. In particular, for indirectly affected medium-sized companies, the law represents a major challenge that can only be mastered with higher-level IT solutions.

Furthermore, 58% mentioned legal uncertainties regarding liability, 55% a lack of alternatives for key suppliers, and 55% a lack of willingness on the part of suppliers to undergo audits as possible challenges to implementation.

Support to the Act’s purpose

Despite the many challenges, most study participants do see the law as an opportunity to improve people's working conditions along the supply chain.

The survey shows that there’s essentially widespread approval for the Act’s purpose with 80% of the respondents hoping for better working conditions for the people who work in companies within the supply chain for chemical products.

Furthermore, almost half of the CHEMonitor survey participants (46%) consider the law necessary because too few companies have so far complied with a voluntary commitment according to the NAP.

In fact, more than half of the survey participants (57%) confirm that voluntary commitments made by the chemical industry to date are not sufficient. For example, only 52% of the companies surveyed currently have a supplier code of conduct in their contracts and only 44% use a management system for human rights and environmental risks.

The Act in the mix of today’s chemical supply chain

Considering this extensive catalog of measures, the question arises as to how much has already been done in the chemical industry in the months since the law was passed and how large the proportion of companies is that have already implemented the required measures on a voluntary basis. The graphic below further illustrates to what extent this has been done by companies with up to as well as over 1000 employees.

Virtual payment as a transparency tool for supply chain visibility

Without the Act, the challenges in the supply chain were already many and now with the Supply Chain Act coming in force with management measures for multiple layers of suppliers and sub-suppliers, every tool to gain total transparency is more than welcome.

With the payment step happening at the beginning of the procure-to-pay process, e.g. for the purchase of raw materials, it’s key that the payment tool can provide further optimization also further down the process.

AirPlus Virtual Cards Procurement is such a virtual payment solution, bringing benefits throughout the entire chain: Designed for the digital age, it can be used for long-tail or recurring expenses with millions of merchants globally according to the Mastercard® network’s wide acceptance.

The virtual credit cards are ideal for supplier payment, while also providing increased control by means of customized security settings you can apply to the cards.

Virtual payments provide end-to-end visibility over spending. The billing data each virtual card can carry throughout the payment process, enrich your transactions, resulting in a seamless reconciliation of your procurement order and supplier’s invoice.

AirPlus Virtual Cards Procurement helps you achieve the transparency you need with billing reports for easy cost allocation, untangling the knots in your supply chain with various orders and suppliers you deal with on a daily basis.

That’s not all, virtual payment can play an important role in optimizing working capital. In fact, through AirPlus Virtual Cards Procurement, AirPlus as the payment solution provider pays suppliers directly. Your company receives, at the end of the reporting period, a single detailed account statement and the expenses are then debited by AirPlus to the centralized account of your organization according to the agreed payment terms.

This allows you to earn more value days than traditional payments by bank transfer or direct debit and to have plenty of time to re-invoice your customer.

On top of this, AirPlus’ solutions can also help your organization report on your sustainability and compliance efforts, which is important for meeting the Act’s regulatory requirements and demonstrating a commitment to responsible business practices.

AirPlus International can help your company by providing the tools and support you need to manage financial and operational risks, ensure compliance with regulations, and operate in a sustainable and responsible manner.

Want to learn more about how virtual payment pays off for your supply chain to stay fit going forward?

Get more information in our Supply Chain Due Diligence Hub by clicking the button below.

Sources:

[1] Overview of the Supply Chain Act | 5-ht.com

[2] FAQ Initiative-Lieferkettengesetz.de

[3] Due diligence Definition & Meaning | Merriam-Webster

[4] CSR - Background and development | csr-in-deutschland.de

[5] Council adopts position on due diligence rules for large companies | Consilium (europa.eu)

[6] What the Chemical Industry Expects from the German Supply Chain Act | Camelot Group

[7] CHEMonitor 02/2021

.jpg?width=375&height=180&name=iStock-1497172728%20(3).jpg)